| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Brand Name : LB

Model Number : LB-110

Certification : CE ISO9001

Place of Origin : ZHANGJIAGANG, JIANGSU

MOQ : 1 SET

Price : USD EUR

Payment Terms : L/C, T/T

Supply Ability : 15 SETS PER MONTH

Delivery Time : 30 WORKING DAYS

Packaging Details : NORMAL PACKAGE

PIPE DIAMETER : 75-250

EXTRUDER'S POWER : 55KW

COLOUR : CUSTOMIZED

PIPE UMBERS : SINGLE PIPE

RAW MATERIAL : PVC POWDER & ADDITIVES

APPLICATION : WATER SUPPLY PIPE

Voltage : 380V 50Hz or customized

Automatic grade : Full-automatically

Screw design : Twin screw and barrel

After-sales service provided : Engineers available to service machinery overseas,Field installation,commissioning and training,Online support,Video technical support

Warranty : 18 months

Inverter : ABB

Color : Customizable

Raw material : PVC Powder

Motor : SIEMENS Brand

Contactor : SIEMENS OR SCHNIDER

Screw and barrel : Conical twin screw extruder

Screw diameter : 65/132

Pipe Application : Water Supply

Packages : Film and boxes

Payment : T/T, L/C, Western Union

Delivery time : 60 days

Plastic PVC Agricultural Irrigation Conduit Water Supply Garden Hose Corrugation Pipe and Extrusion Making Machine

Short desciption

Our high-quality PVC Agricultural Irrigation Conduit and Garden Hose Corrugation Pipe are designed for efficient water supply, drainage, and irrigation systems. Made from durable UV-resistant PVC material, these pipes offer excellent flexibility, corrosion resistance, and long-lasting performance in agricultural, landscaping, and industrial applications.

Tech Features & Advantages

energy saving and ECO system (15% down),

high standard (Bimetallic & PLC Intelligence),

reliable quality (vertical gearbox with SKF thrust bearing)

Producting process

PVC powder + additive → mixing → spring feeding → twin screw extruder → mould and calibrator → vacuum forming machine → haul off machine → cutting machine → stacker

Specifications:

| MODEL | PIPE DIAMETER (MM) | EXTRUDER MODEL | MOTOR POWER (KW) |

| LB-32F | 16-32 (FOUR PIPE) | SJSZ65/132 | 37 AC |

| LB-32E | 16-32 (DOUBLE PIPE) | SJSZ51/105 | 22 AC |

| LB-32W | 16-32 (DOUBLE PIPE) | SJSZ65/132 | 37 AC |

| LB-40E | 16-40 (DOUBLE PIPE) | SJSZ51/105 | 22 AC |

| LB-40W | 16-40 (DOUBLE PIPE) | SJSZ65/132 | 37 AC |

| LB-50E | 16-50 (DOUBLE PIPE) | SJSZ51/105 | 22 AC |

| LB-50W | 16-50 (DOUBLE PIPE) | SJSZ65/132 | 37 AC |

| LB-63W | 16-63 (DOUBLE PIPE) | SJSZ65/132 | 37 AC |

Product detail

1. Raw Material Mixing & Feeding

PVC resin, stabilizers, plasticizers, and other additives are precisely weighed and mixed in an automatic mixer.

- The blended material is fed into the hopper of the extruder.

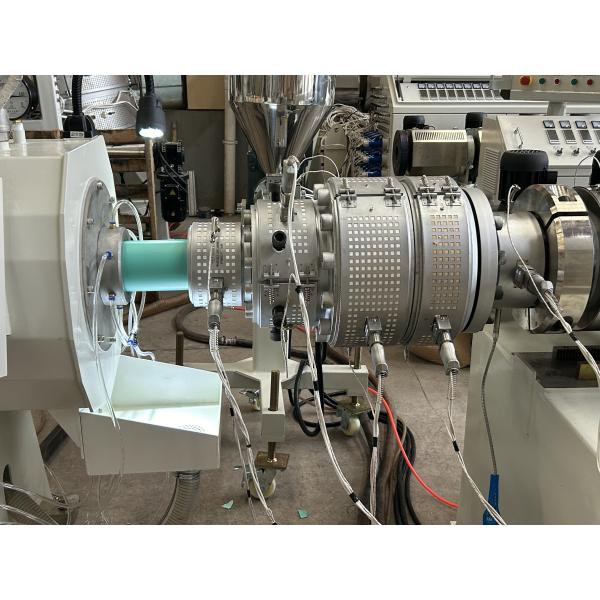

2. Extrusion & Pipe Forming

- The twin-screw extruder heats and melts the PVC mixture, pushing it through a die head to form a continuous pipe shape.

- The pipe diameter and wall thickness are controlled by the extrusion die and sizing sleeve.

3. Vacuum Sizing & Cooling

- The newly formed pipe passes through a vacuum sizing tank to ensure precise dimensions.

- It then enters a cooling water tank to solidify the structure and maintain shape stability.

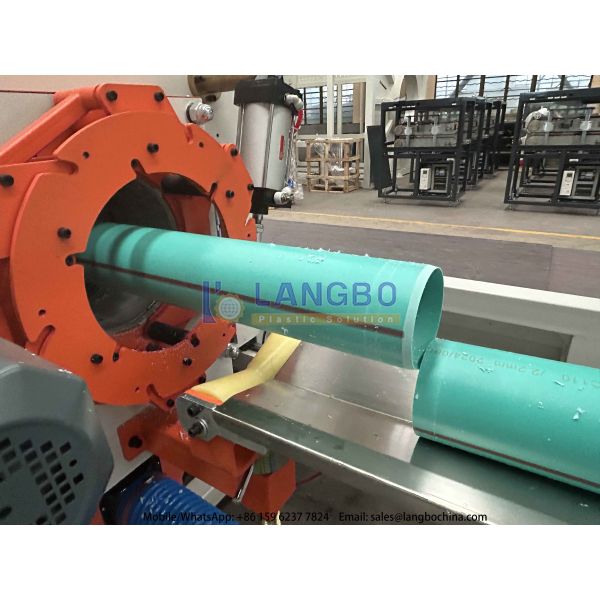

4. Hauling & Cutting

- A haul-off machine pulls the pipe at a controlled speed to maintain consistency. - An automatic cutting machine cuts the pipe into desired lengths (e.g., 4m, 6m). 5. Stacking & Packaging

- The finished pipes are automatically stacked and packed for storage or shipment.

|

|

Plastic PVC Agricultural Irrigation Conduit Water Supply Garden Hose Corrugation Pipe And Extrusion Making Machine Images |